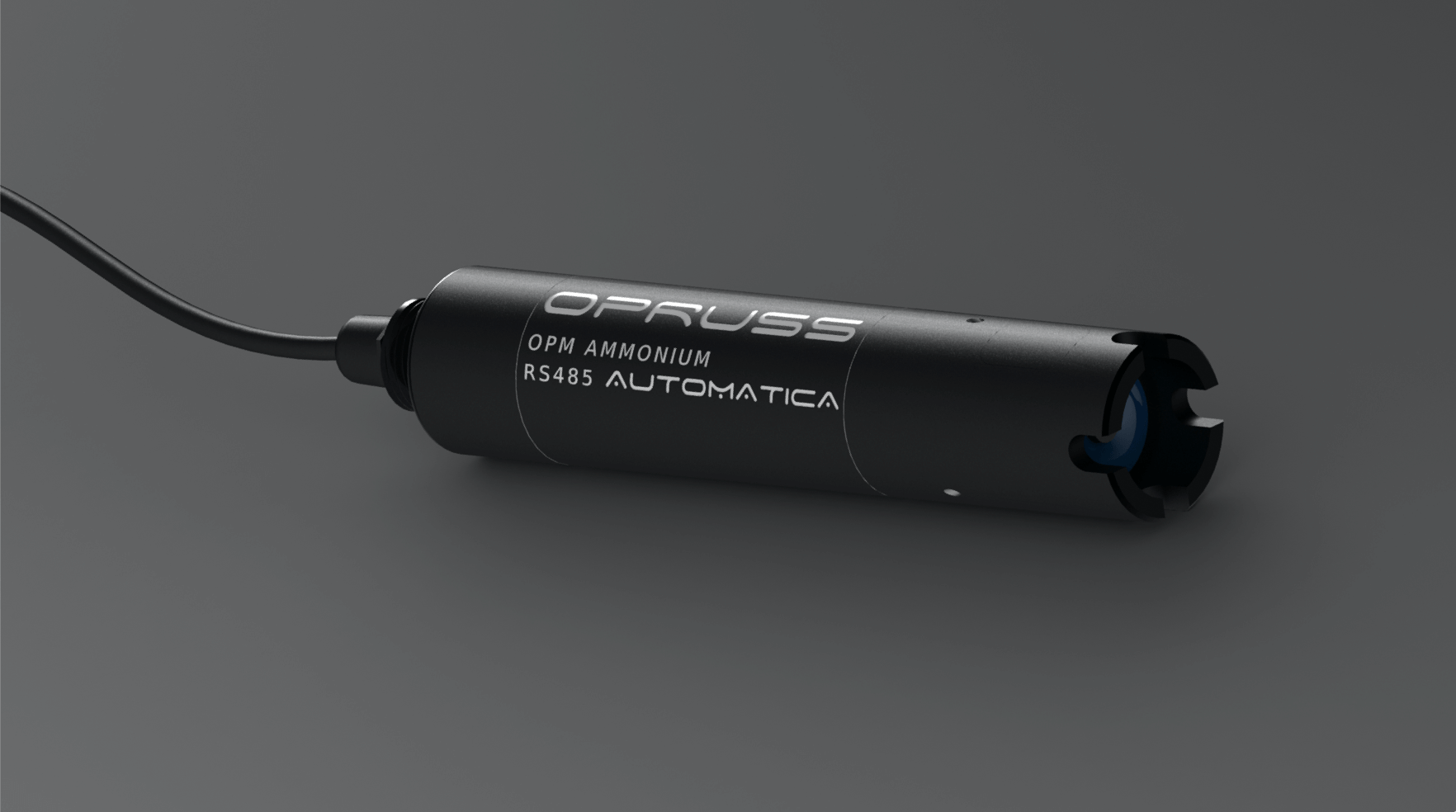

OPM AMMONIUM

Sensor for measuring NH4+ ions in aqueous medium

- RS485 Digital signal output

- Plug and play design

- Ultra-rigid cable for on-field use

- Enabled with remote accessed calibration

- Non-corrosive POM PEEK shell

- Built in interference cancellation

- Compatible with Cleaning system assembly

- Advanced diagnostics enabled system

- Equipped with improved Selective Ions Electrode

- Accurate and repeatable readings

- Shock proof sensor aperture

- Adaptability to several water matrices

The OPM AMMONIUM (NH4) ion selective sensor that can be used in heavy industrial process as well as the wastewater treatment systems, providing measurements up to saturated levels and can operate continuously without any chemical reagent or human intervention or interference

OPM AMMONIUM sensor provides an unrivalled and proven solution for Ammonium measurement. The ISE sensor is capable of measurement of fine traces right from 0.090 to stronger concentration 18,000 ppm (5X10-6 to 1.0 Molar) and its lowest limit of detection is 0.004 ppm (5X10-7 Molar).

For applications where the pH is above 8.0, a pH sensor is added to the analyser to provide compensation of both pH and temperature. The sum of the measured unbound ammonium ions and dissolved ammonia gas formed are computed as a function of both real-time continuous pH & temperature parameters.

OPM AMMONIUM is specially developed for field use with harsh conditions, operate with stable performance, consumable and maintenance free regularities while continuously used

Sources:

1. Landfill leachate:

The generation of leachate is caused principally by precipitation percolating through waste deposited in a landfill. Once in contact with decomposing solid waste, the percolating water becomes contaminated, and if it then flows out of the waste material it is termed leachate.

2. Waste products:

Big factories flush down waste products in the water, and this is one of the major causes of ocean pollution.

3. Sewage

Sewage is a type of wastewater that is produced by a community of people. It consists mostly of grey water (from sinks, bathtubs, showers, dishwashers, and clothes washers), black water (the water used to flush toilets, combined with the human waste that it flushes away), soaps and detergents; and toilet paper.

The process of ammonification continues in the sewage treatment plant, so that most of the nitrogen in the inflow to the aeration tank is in the form of NH4-N.

4. Liquid manure

Liquid manure is a mixture of urine, water, and faeces. Livestock urine usually contains more than 55% of the excreted N, of which more than 70% is in the form of urea. Hydrolysis of urea by the enzyme urea produces ammonium (NH4+) and carbonate.

5. Liquid organic waste products

. “organic liquid waste” is classified into six types: “general liquid waste,” “hazardous waste solvents,” “nonflammable liquid waste,” “highly flammable waste,” “waste oils,” and “other organic waste.”

Limits:

Soils can tolerate ammonia amounts to 10-90 mg/ Kg in course textured soils, 60-270 mg /kg in medium textured soils and 90-260 mg/kg in fine textured soils.

For typical municipal domestic wastewater (little or no industrial wastewater), the ammonium-N is typically between 20-40 mg/L depending on the strength of wastewater. Higher values exceeding 50 mg/L is also possible depending upon wastewater strength.

For industrial, it is industry specific and could be very low (few mg/L) to >>1000 mg/L.

Chemical Stability:

Ammonium is a weak acid. NH4+ is the ammonium ion. It has a positive charge and a molecular weight of 18g/mol. NH4-N is the nitrogen content of the ammonium ion.

Features

- Exact and reliable real-time measurement

- Long-term stable measurement

- No additional conditioning reagents necessary

- OPM AMMONIUM is an all inclusive system requiring no reagents, or mechanical devices for performing.

- The core is ion selective electrode with a mono-crystal sensing element specially developed from maintenance free solid state reference system.

- Specially developed anti fouling aperture components reduce the ability of surface depositions, also comes with a non-porous electrode to reduce surface depositions

- Features a smart built in compensation of error due to temperature and potential noise

- Outputs sensor diagnostics data to closely and continuously track field performance without the need of physical access

- Comes with a easy plug and play design that is robust enough for industrial application

Installation methods

Medium immersed

- Sites with challenges like a distant medium source from the point of controller mount, this method of installation can be chosen.

- The analyser being constantly in contact with the medium helps the analyser to never face a dry-off situation

Extractive

Where the sample enters and exits the system like a standard stationed measuring device. Usually avoids the Constantine medium matrix as the sample with variating quality flows through the device rather than a partially stagnant volume of medium. Sample extraction accessory is required for this type